A manager is someone who has control over a company. They are given the responsibility of overseeing what the company does and making important decisions. The manager is the most important person in the empire and needs to be in the know at all times. Not what happened a day ago but in real-time and from any place.

Information is necessary for this to happen. It needs to be concise, brief and straightforward. Ideally, access to job status, location information, customer information, notifications and location information should be on the palms of their hands.

To sum it all up, there should be fluid communication among personnel in the field. Information should be accessed easily from one place as it flows to another to maintain steady two-way communication. This is possible with automation meaning that no amount of data will be left unseen or unused because of paperwork that was never handed over or looked into, reducing the chance of misinformation or missing information to a minimum.

Ways improved visibility will help your business through Field Service

Organisations using field services will agree that improved visibility has more business benefits and the real question is what aspect needs improving rather than discussing the benefits.

Real-time visibility

Managers need to be in the know from anywhere at any time. The manager needs information about the company. The need not to be physically present to have an idea of what’s going on. They should know everything at all times, from what was planned for the day to real-time events.

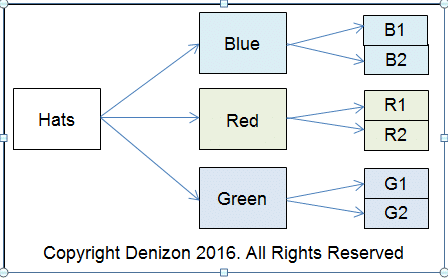

All this information should be easily accessed from one central point and should contain everything about the company and other relevant information.

Extending the back office into the field

This two-way communication is virtually irreplaceable. At any time, the information should flow among technicians in the field and those in the back office. This will help to have a better idea of how to manage the workload and come up with solutions to some work-related issues.

Everyone in the team should be informed and be up to speed about real-time events. Keeping everyone updated improves visibility because they can make updates and decisions based on the kind of information they get.

No more lost paperwork

Managing paper trail can be quite a hassle for organisations. With tons of workload, there can be many delays meaning that some information might be missed or forgotten. People might also choose not to turn up for work for days on end and can affect how much info is processed. Some work can be left undone, and work not invoiced.

When organisations use field service management services, information is fed only once and everything else is done automatically. Say goodbye to lags or relying on last month?s data. Work will move faster because people will have more time to focus on important things rather than chasing an endless paper trail.

Business intelligence

Field service management technology will let you know what is being done in the field and with such an abundance of data, will make sound decisions for the business.

Every decision is hinged on cold facts. Information needs to be easily accessed and filtered into the right categories so that sound business decisions are made from the collected data.

Growing revenue

The abundance of real-time information and improved visibility can determine whether a business will grow or not. Each piece of information can show trends that are critical for any business to improve. Trends show how each sector is doing and sheds more light into specific areas that need a total overhaul. This may include improving customer service, products on retail or hiring more technicians.

Without information, a company is one step closer to going out of business. Every action should be geared to increase the revenue and this starts by making the right choices.

Visibility when working offline

Working offline is an issue that can affect visibility. Sometimes agents will need to work in areas that have little network coverage or are deep down working in tunnels or are around heavy machines and turbines. Field service solutions are built for the mobile environment and for workers who may find themselves in non-connected areas so that they can still use their device while offline. This makes sure that there is no loss of information while working in-field

Time-saving

Certainly, business is constrained to its environments and if the demand changes it should prove to be flexible enough to adjust to changes as they happen. Field service solutions operations like schedule need to update instantly. Once activities start rolling, nothing should create lags in the schedule so that operations flow seamlessly at all time.

Field workers can then make updates and document changes easily on the job site directly on their device by using responsive site menus, drastically saving time while feeding data and complete orders.

Improved customer service

It is not a clich? to say that the customer is always right. With real-time information, both field service and back-office technicians can improve customer relations and satisfaction. With a unified system of sharing information like the ERPs and CRMs, the field officer can know more about specific clients, their history and other data to know more about what should be done in current and future orders. This means that better decisions will be made for each customer.

How improved visibility benefits different parts of the organisation

Improved visibility in all areas of the business makes information more accessible. Here are some of the benefits that various sects of a business can get from improved visibility.

? The business owner

The manager owns the company and can access all information with just a single tap. A lot of data can be used to analyse the health of the venture. This includes revenue, inventory, customer surveys, employee hours, invoices and customer data.

Profitability is increased by putting more emphasis on customer satisfaction and improving the quality of end products and services.

? The service manager

The service manager can see what is going on in the field in real-time, and look into measures that can improve the productivity of staff members in various departments.

And with workflow automation, time-saving is at the maximum because there is less paperwork consequently improving scheduling and job completion rates.

? Service administrator/ dispatcher

For the team in the office, they can assign tasks faster. Scheduling is automatically done and updated in real-time. It eliminates the need for paperwork and leaves more time to be productive on other errands.

? The field technician

Improved visibility for a field worker means that they can do their best in any task. They can share or get critical information about orders and customers. This drastically improves job completion rates and customer satisfaction.

? HR

Live information can be used to track certain orders, the time it takes to complete orders, and the number of staff required in the organisation. Such data can be used in HR to reduce payroll errors and erroneous overtime costs.

? Finance

Field service management software can also benefit the finance team by automation of invoices. A work order can be tracked from start to the end and invoiced immediately to retain faster payments. Relevant data can be used to track revenue and expenditures, and costs.

Real-time visibility gives a company many solutions to manage the workload. In the end, visibility is also useful in increasing revenue and a smooth transition of information for the company.