Tightening organisational flow to improve productivity and minimise costs is a growing concern for many businesses post the Global Financial Crisis. Businesses can no longer afford to waste time and personnel on inefficient processes. Organisations using either Six Sigma or Lean techniques better manage their existing resources to maximise product out-put. Both of these techniques involve considerable evaluation of current processes.

What is Six Sigma?

Six Sigma is an organisational management strategy that evaluates processes for variation. In the Six Sigma model, variation equates waste. Eliminating variation for customer fulfilment allows a business to better serve the end-user. In this thought model, the only way to streamline processes is to use statistical data. Each part of a process must be carefully recorded and analysed for variation and potential improvements. The heart of the strategy embodied by Six Sigma is mathematical. Every process is subject to mathematical analysis and this allows for the most effective problem solving.

What is a Lean Model?

Lean businesses do not rely on mathematical models for improvement. Instead, the focus is on reducing steps in the customer delivery cycle, which do not add value to the final deliverable. For example, maintaining excess inventory or dealing with shortages would both be examples of waste behaviour. Businesses that operate using Lean strategies have strong cash flow cycles. One of the best and most famous examples of Lean in action is the Toyota Production System (TPS). In this system, not only is inventory minimised, but physical movement for employees also remains sharply controlled. Employees are able to reach everything needed to accomplish their tasks, without leaving the immediate area. By reducing the amount of movement needed to work, companies also remove wasted employee time.

Industry Applications for Lean and Six Sigma

Lean businesses reduce the number of steps between order and delivery. The less inventory on hand, the less it costs a business to operate. In industries where it is possible to create to order, Lean thinking offers significant advantages. Lean is best utilised in mature businesses. New companies, operating on a youthful model, may not be able to identify wasteful processes. Six Sigma has shown its value across industries through several evolution’s. Its focus on quality of process makes it a good choice for even brand new businesses. The best use is the combination of the two strategies. With the Lean focus on speed and the Six Sigma focus on quality combined, the two organisational processes create synergy. By itself, Lean does not help create stable, repeating success. Six Sigma does not help increase speed and reduce non value-added behaviours. Combined, these two strategies offer incredible value to every business in cost savings.

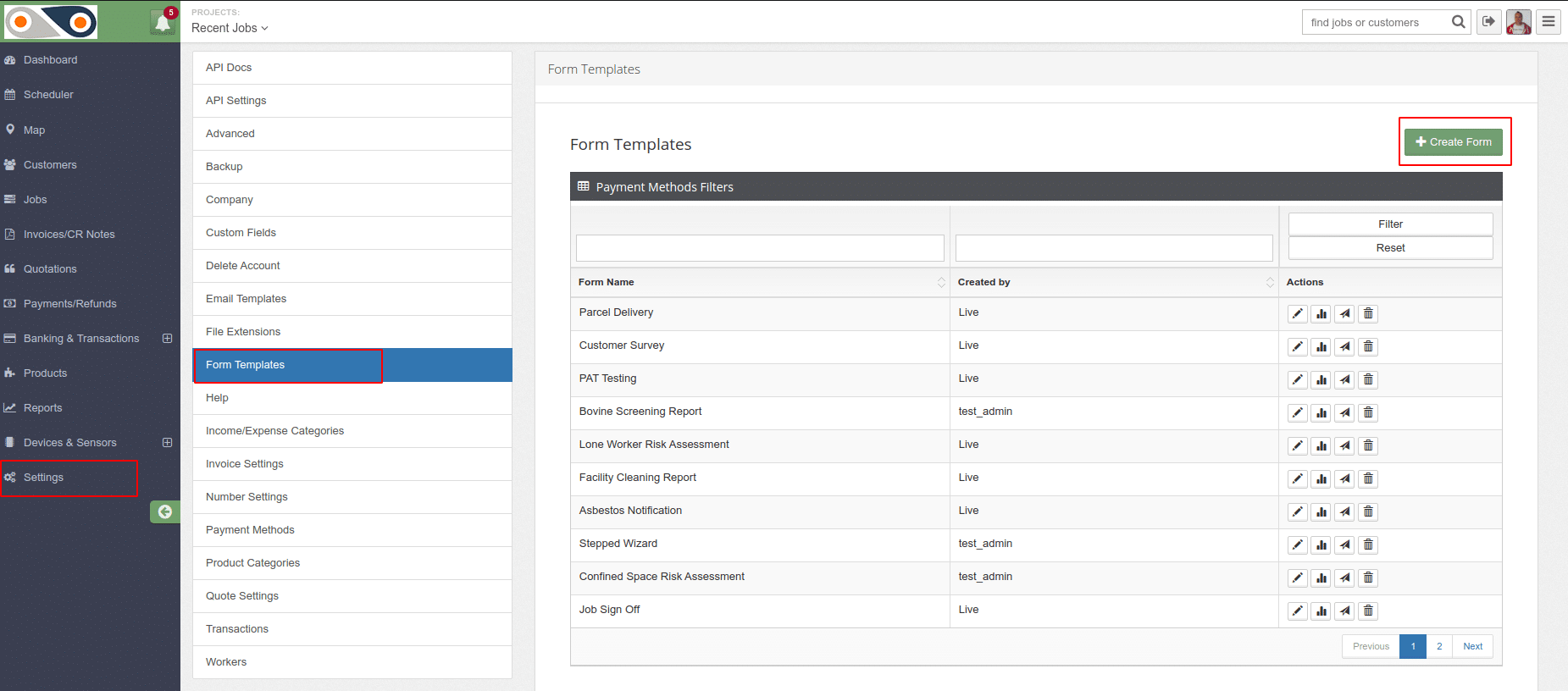

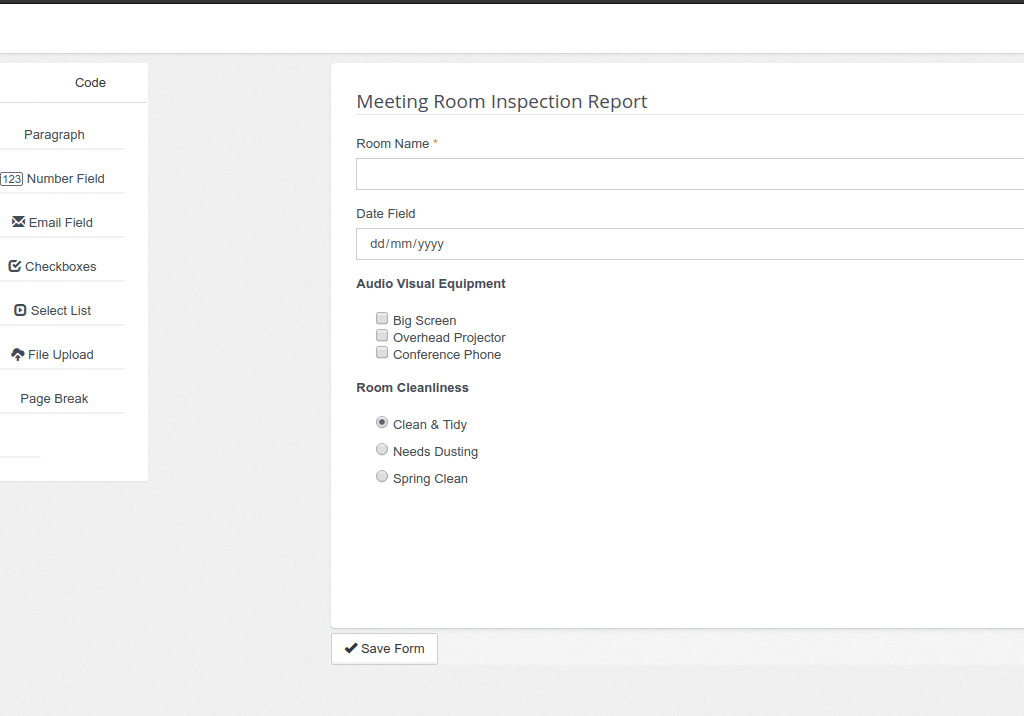

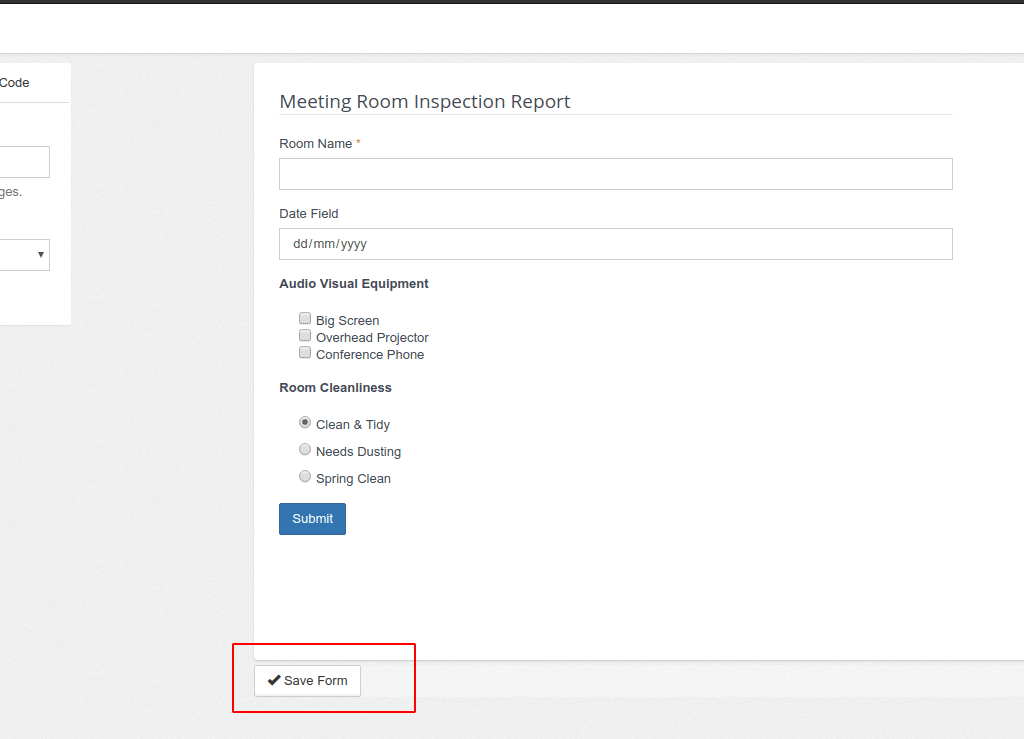

Using Technology to Implement Lean Six Sigma

Automation processes represent an opportunity for businesses to implement a combination of both Lean and Six Sigma strategies. Any technology that replaces the need for direct human oversight reduces costs and increases productivity. A few examples of potentially cost saving IT solutions include document scanning, the Internet, and automated workflow systems.

- Document Scanning – Reducing dependency on paper copies follows both Lean and Six Sigma strategies. It is a Lean addition in that it allows employees to access documents instantly from any physical location. It is Six Sigma compliant in that it allows a reduction on process variation, since there is no bottleneck on the flow of information.

- The Internet – The automation potential offered by the Internet is limitless. Now, businesses can enter orders, manage logistics and perform customer service activities from anywhere, through a hosted portal. With instant access to corporate processes from anywhere, businesses can manage workflow globally, allowing them to realise cost savings from decentralisation.

- Automated Work Systems – One of the identified areas of waste in any business is processing time. The faster orders are processed and delivered, the greater the profits for the company and the less the expense per order. When orders sit waiting for attention, they represent lost productivity and waste. Automated work systems monitor workflow and alert users when an item sits longer than normal. These systems can also reroute work to an available employee when the original worker is tied up.

Each of these IT solutions provides a method for businesses to either reduce the number of steps in a process or improve the quality of the process for improved customer service.

Identifying Areas for Lean Six Sigma Implementation

Knowing that improved processes result in improved profits, identifying areas for improvement is the next step. There are several techniques for creating tighter processes with less waste and higher quality. Value Stream Mapping helps business owners and managers identify areas of waste by providing a visual representation of the total process stream. Instead of improving single areas for minimal increases in productivity, VSM shows the entire business structure and flow, allowing management to target each area of slow down for maximum improvement in all areas.

Seeing the areas of waste helps management better determine how processes should work to best obtain the desired outcomes. Adding in automated processes helps with improved process management, when put in place with a complete understanding of current systems and their weaknesses. Start with mapping and gain a bird’s-eye view of the situation, in order to make the changes needed for improvement.

Contact Us

-

(+353)(0)1-443-3807 – IRL

-

(+44)(0)20-7193-9751 – UK